PROM FORM

-60°С

-60°С

+100°С

+100°С

Certification

RU-FLEX PROM FORM coating (silver)* is a combined fiberglass material laminated with aluminum foil and intended for use as a coating layer for items located in rooms and tunnels. Provides protection from ultraviolet exposure and mechanical impact.

RU-FLEX PROM FORM coating is all-purpose, does not rust, and is resistant to surface heating by sunlight. The wide temperature range of application allows the coating to be used in various climatic regions.

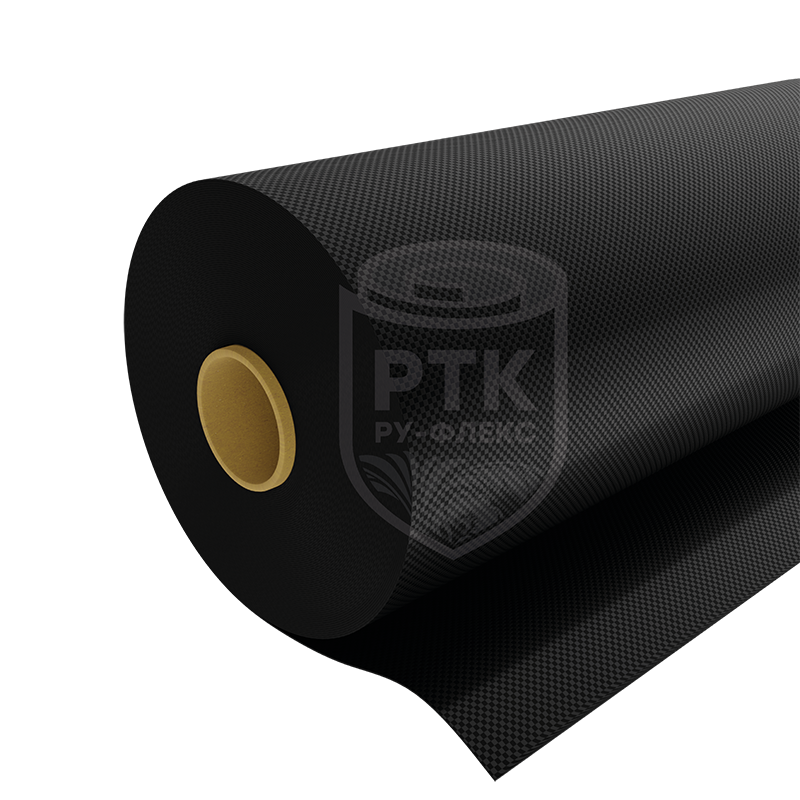

RU-FLEX PROM FORM coating (black) is a fiberglass material (without an aluminum layer) intended for use as a coating layer for items located in rooms and tunnels. It provides protection from ultraviolet exposure and mechanical impact.

Areas of application:

- industrial and civil construction;

- all types of offshore rig;

- electric power industry;

- naval construction and civil shipbuilding;

- oil and gas industry, chemical, mining and fuel industries;

- combined heat power plants.

Application

Application

- Shipbuilding

- All types of offshore rig

- Oil and gas industry, chemical, mining and fuel industries

- Industrial and civil construction

- Heat-power engineering

- Electrical energy industry

- Other coatings of RU-FLEX

- RU-FLEX PROM FORM

- RU-FLEX PROM ALU

- RU-FLEX ALU

- RU-FLEX PROM POLYMER